12 Dec Protect Yourself and Your Co-Workers When Operating Equipment

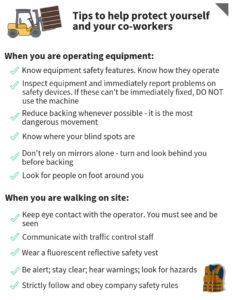

Forklift or lift truck operators must follow safe operating rules at all times.

Only a trained and authorized employee is allowed to operate any type of forklift.

Operators must always maintain control of the forklift, keep a proper lookout, and operate the forklift at speeds safe for the particular operation and worksite conditions.

If the “powered industrial trucks” are not handled properly, these powerful machines can cause serious injuries, property damage, and even death.

Before operating a lift truck, you should be properly trained and be able to identify the four categories of lift trucks, recognize common causes of lift truck accidents and describe the basic controls and features of lift trucks.

Types of Forklifts

Forklifts can be powered by electric of internal combustion engines. They are categorized by following four power sources: gasoline, diesel, propane, electric.

Forklifts are then broken down into different categories, depending on the safeguards and features that exist.

It is important to know the type of lift truck you are operating because it may not be compatible with potentially hazardous atmospheres in your work area.

For example, Safety National states, “a truck designated as “G” is not approved for operation in an atmosphere with flammable dust or vapors, or an enclosed area in which the carbon monoxide from exhaust would exceed established permissible exposure levels.”

Fork Lift Accidents

Did you know that each year there are more than 37,000 forklift-related injuries?

Out of the 37,000 injuries, nearly 20,000 of them are serious injuries; forklift overturns being the leading cause of fatalities.

Along with the injuries and deaths caused by lift trucks, millions of dollars are also lost in damaged equipment, destroyed products, or missed shipments.

The most potential hazards can include:

- Hitting head on overhead cage

- Slips, trips, and falls, especially feet slipping off step

- Tipping Over

- Striking or crushing a co-worker

- Being struck by a falling object

- Crashing into fixed objects

- Loads falling off the forks

- Riders falling from the lift truck

Your understanding of how to identify and avoid common hazards created when operating a fork lift will ensure your safety and the safety of others in your work area.

Your Responsibility

As a lift truck operator, it is your responsibility to know the controls and features of your truck.

A typical forklift has two main components: the body and the hydraulic lift. All forklifts are equipped with a parking brake and a horn. Most have headlights, taillights, brake lights, backup lighting, and alarms.

You must be properly trained and be very familiar with this information before operating a lift truck.

Synergy Comp’s Free Safety Resources

Safety National is an online training resource that improves the safety performance of your whole team while building a culture of safety. The online training resource covers a broad range of topics related to your business including the topic, Forklift Safety.

Proper forklift training will educate you and your team on how to recognize and avoid common hazards when operating a lift truck.

The online, Safety National, training goes in depth by educating supervisors and employees on forklift safety topics including:

- How Forklifts Work

- Pre-Operation Inspection

- Proper Load Handling

- Safe Driving Skills

- Refueling & Battery Changing

Synergy offers several other safety resources to all current active clients that focus on the specific changes and challenges that are unique to all businesses. The trainings are industry specific and cater to your exact line of business. The online resource will be free of charge; not only saving time but money.

If you are interested in partnering with Synergy Comp and SOS Safety Solutions to create a culture that fosters communication and embraces safety as a core operating principle, Contact Us Today!

No Comments